Master Roller strongly beleives the Environmental influence,better environment creating better performance.

Base shell is the the most basic and important element for cylinders quality. Master Roller has been using seamless pipe (Thickness8-10mm) making base shell to maintain the high quality standard position in local market.

The branded CNC Lathe machine for rough and fine turning of base shells, it ensures the basic precision of base shells at the initial step.

Luvata is a leading supplier of copper anodes for electroplating. Our copper anodes importeded from Luvata is the purest electrolytically refined copper cathodes, which are melted under strictly controlled conditions to guarantee the perfect copper layer for engraving.

The Deatewaler CFM make the perfect entry-level solution for processing before engraving which is the most important process for cylinders precision and stable performances at customers’ end.

With Daetwyler GS, Hell K5 Smart, Ohio Gravure Engraving System, Master Roller can meet various needs of customers and provide the most competitive engraving quality in local market.

Chrome plating is the most important point concern the cylinder life, Chromium Trioxide imported form Bayer Germany is the main point Master Roller’s cylinder life has always maintaining the toppest rank in the fierce competitive market in Thailand.

KW Video Met is the latest instrument for Cell checking which is the main tools for QC department.

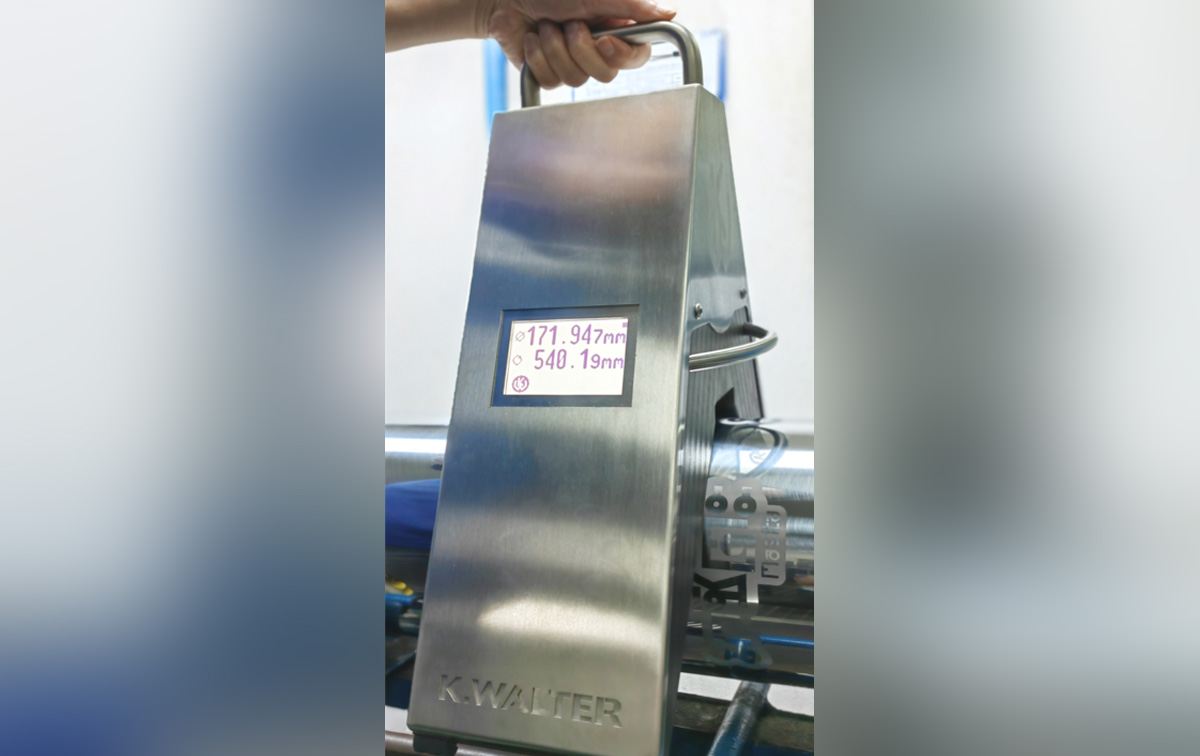

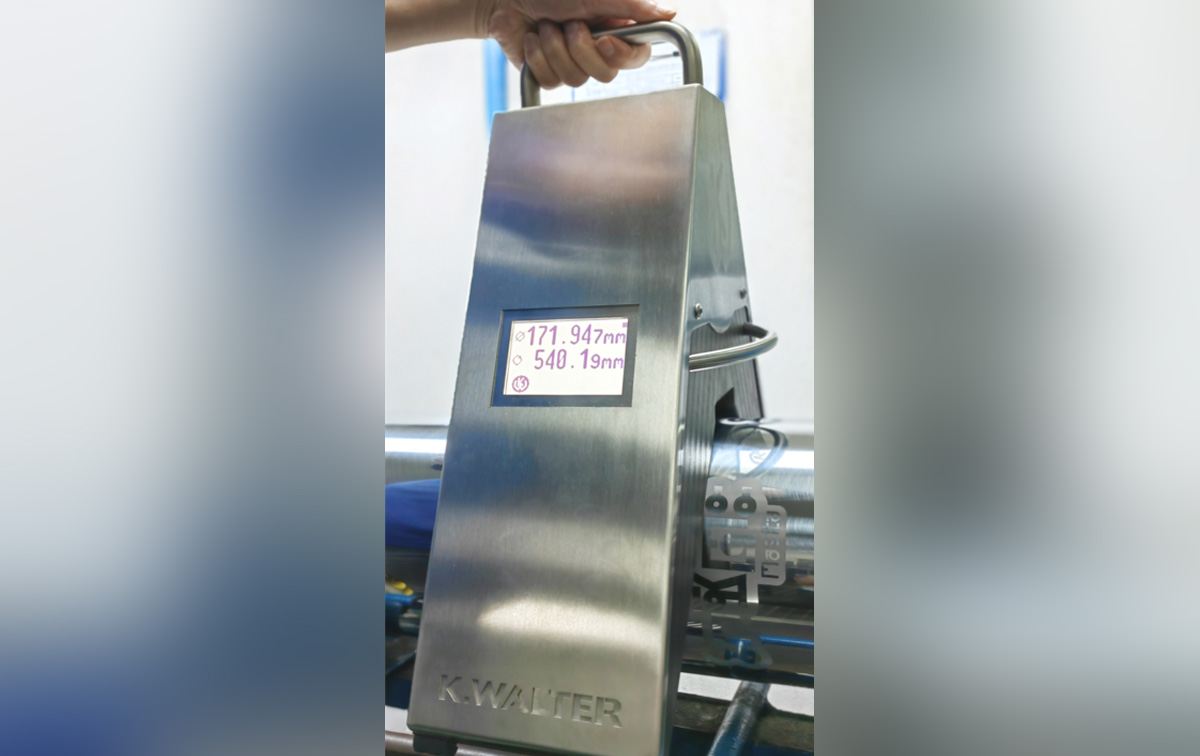

KW Diameter is the latest instrument for cylinder size checking which is the main tools for QC department.

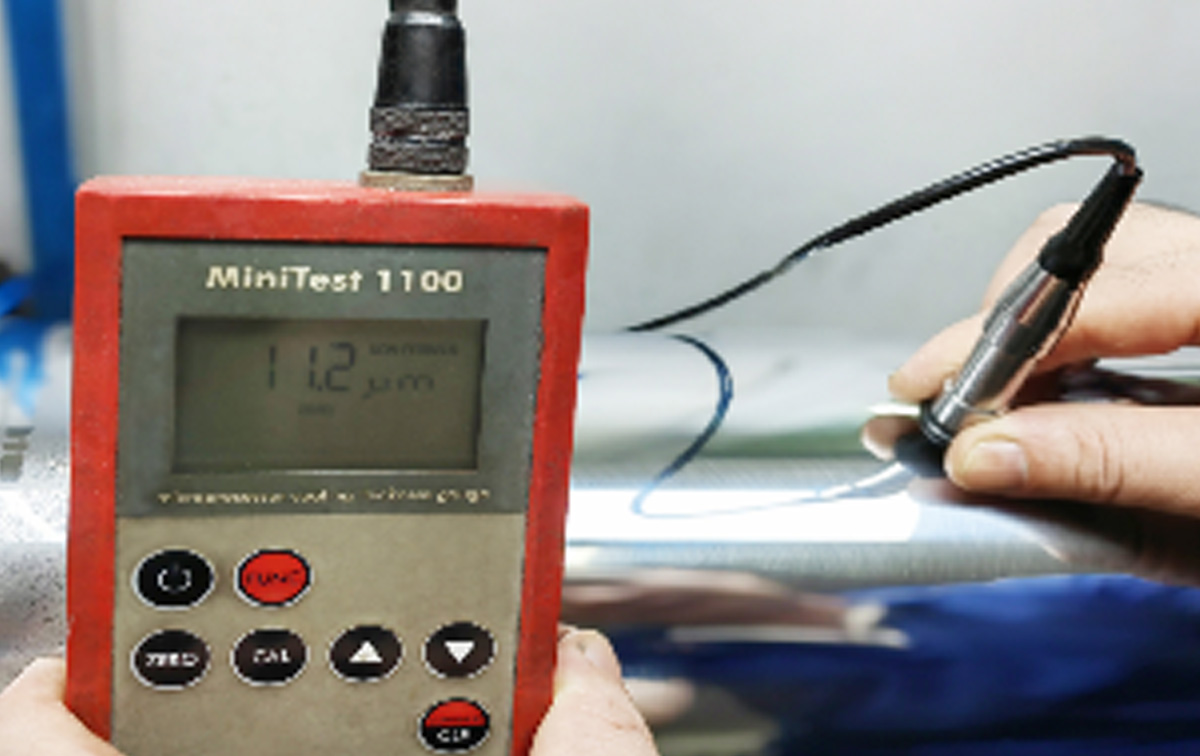

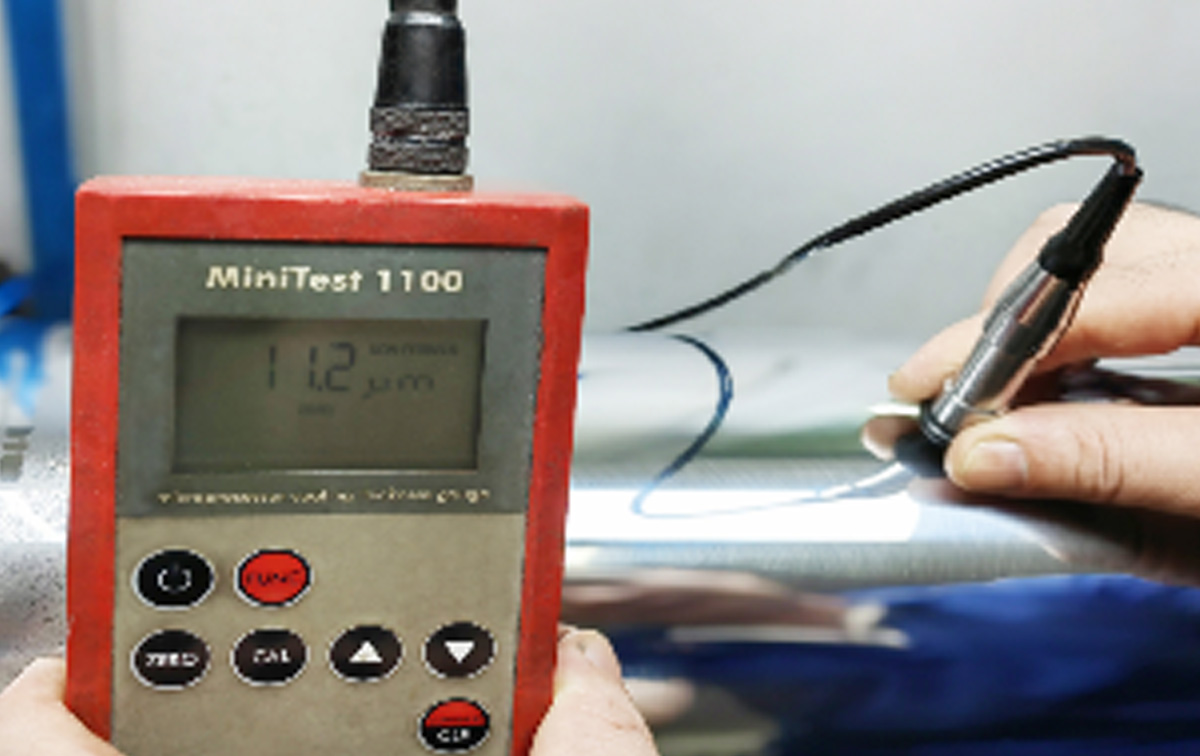

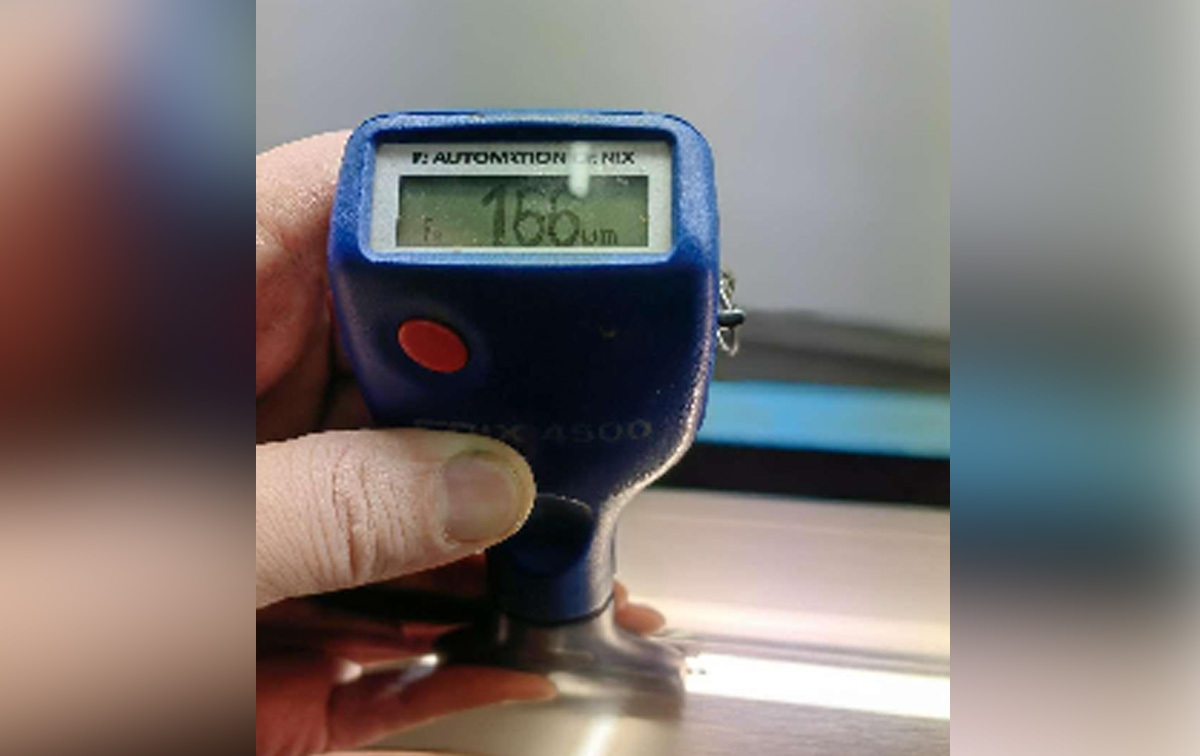

For ensuring the zero erros before delivery, QC department takes full implementation of the sandard in each process strictly and all-round checking and testing before delivery, such as Cell values, Chrome Hardness, Cylinder sizes, Barrel proof results etc .

For ensuring the zero erros before delivery, QC department takes full implementation of the sandard in each process strictly and all-round checking and testing before delivery, such as Cell values, Chrome Hardness, Cylinder sizes, Barrel proof results etc .

With GMG and other latest instruments, our colour management engineer maintain the ICC and all kinds of engraving curves ensuring the well coordinated to achieve the best effect betwenn Digital proof, Cylinder proof and Final printing result at customers end.

Our skilled graphic operator edit and process the images, texts, trapping etc ensuring the excellent printing results according to the different substrates. No matter which ink system or spot colour, we can meet the specific reproduction results perfectly by our experiences and technologies.

Maintaining the uniform color results between digital proof and cylinder proof is the advantage of Master Roller even for spot color or Pantone color. Customers can show our cylinder proof to their clients directly for the order confirmation.